Water Treatment Technology

Disinfection system

The disinfection of drinking water , swimming and wading pool water , process water , cooling water and waste water ,different methods are used , these differ in their technical construction and in the type of chemicals used.Our systems are designed to Din standards and ensure optimum water quality through precisely measured disinfection. We apply our know-how and experience to find the best solution- technically and scientifically.

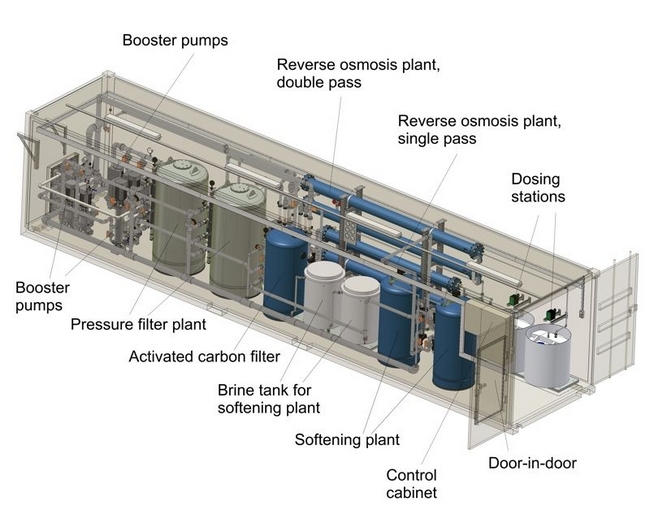

Softener & Filtration Systems

The softener , send and carbon filters are available in wide range of self-contained packages configured in cation resin , single , double and multiple unit arrangements to remove scale forming calcium and magnesium, sediment, turbidity, color, orders, and suspended particles.

Standard & features 1

1.Charged with high exchange capacity cation sodium form ion exchange resin.

2.The raw water is filtered through a filter media of multi grade sand & pebbles (MGF) unit in order to remove suspended matter, turbidity, and colloidal matter present in the feed water.

3.The sand filter is made-up of either |MS inside FRP coated system, or FPR molded vessel depending on the capacity, and requirement.

4.Internally, it is fitted with inlet distributor and bottom collecting system.

2.The raw water is filtered through a filter media of multi grade sand & pebbles (MGF) unit in order to remove suspended matter, turbidity, and colloidal matter present in the feed water.

3.The sand filter is made-up of either |MS inside FRP coated system, or FPR molded vessel depending on the capacity, and requirement.

4.Internally, it is fitted with inlet distributor and bottom collecting system.

Standard & features 2

1.Externally it equipped with extra strong rigid PVC, or MS frontal pipe work with necessary valves & fittings.

2.Unit is charged with different grades of filtering river bed sand, pebbles, activated carbon and filtering media.

3.The filter is isolated for backwash when the pressure drop across the filtering bed is more than specific limit.

4.Ability to withstand corrosive environments.

5.Simple operation reduces operator training requirements.

2.Unit is charged with different grades of filtering river bed sand, pebbles, activated carbon and filtering media.

3.The filter is isolated for backwash when the pressure drop across the filtering bed is more than specific limit.

4.Ability to withstand corrosive environments.

5.Simple operation reduces operator training requirements.

Industrial &Commercial reverse osmosis plant

The reverse osmosis process uses a semi-permeable to separate and remove dissolved solids, organics, pyrogens, submicron colloidal matter, viruses and bacteria from water.

Standard & features

1.Built in safety features to protect high pressure pump and membranes.

2.Capable of handling water with TDS levels between 25000 & 1500 ppm.

3.Efficiently removes up to 95% of TDS salinity to produce water that is clear and pleasant to teste.

2.Capable of handling water with TDS levels between 25000 & 1500 ppm.

3.Efficiently removes up to 95% of TDS salinity to produce water that is clear and pleasant to teste.

Advantages

1.Easy availability of spares and after sale service.

2.Easy to startup and uses very little space on installation.

3.The most economical & efficient method for removal of dissolved solids.

2.Easy to startup and uses very little space on installation.

3.The most economical & efficient method for removal of dissolved solids.

Brands

Power Stations

Oil & Gas

Oil Refineries

Pharmaceuticals.

Petro-chemicals

Engineering Industries

Food & juice Industries.

Solar Systems

Automobile

Textiles

Building Management

Mechanical Industries